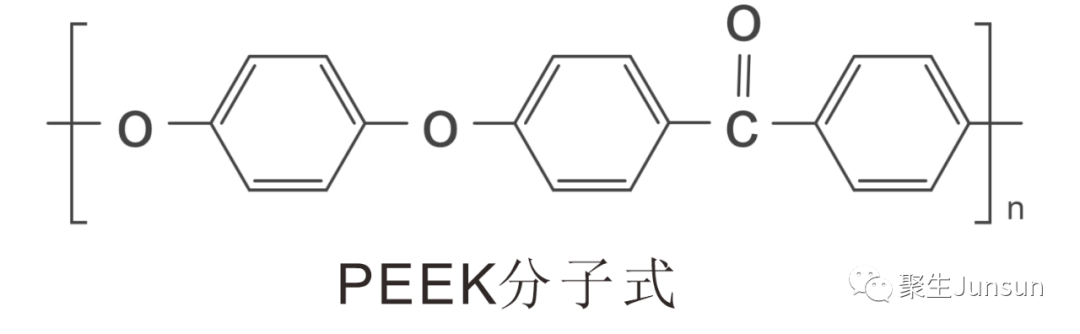

What is peek?

Poly ether ketone (PEEK) is a high polymer composed of two ether bonds and one ketone bond in the main chain structure. It is a special polymer material. It is a material series of poly (aryl ether ketone). It has the characteristics of semi crystalline state, high temperature resistance, chemical corrosion resistance and so on.

Characteristics of PEEK

Polyether ether ketone (PEEK) is the only kind of poly (aryl ether ketone) (Paek) material that can be mass produced at present. As a special engineering plastic, peek has super excellent comprehensive properties.

Typical characteristics of PEEK:

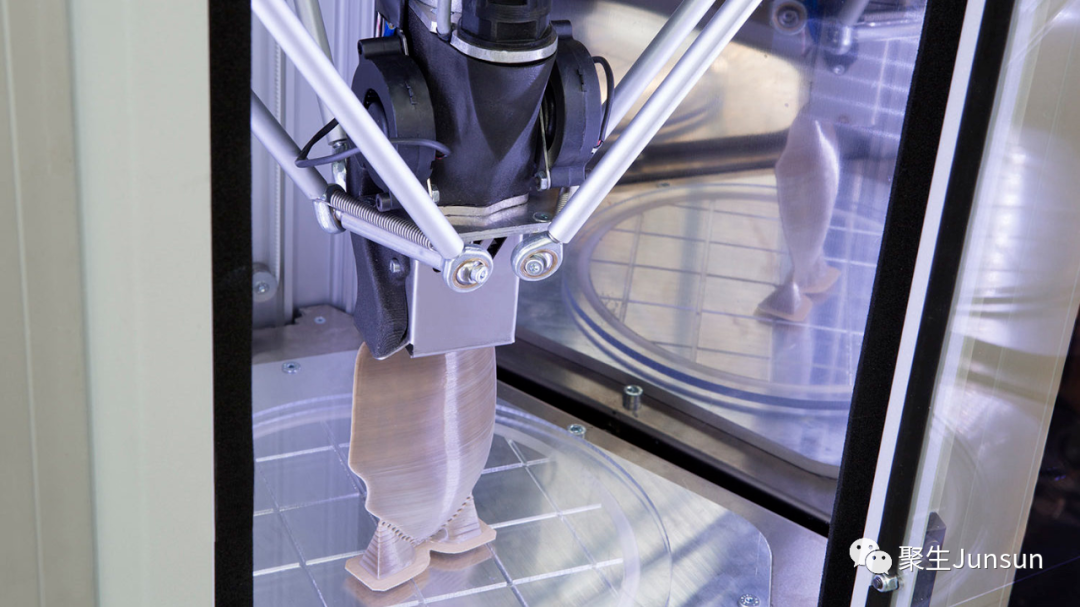

(1) Processability: PEEK resin has the advantages of good high-temperature fluidity and high thermal decomposition temperature. It can be processed by injection molding, extrusion molding, molding, blow molding, melt spinning, rotary molding and powder spraying.

(2) Radiation resistance: it has extremely strong radiation resistance at high doses γ The mechanical properties under X-rays can still be completely retained, which exceeds that of polystyrene with the best radiation resistance in general resins. It can be used as radiation resistant parts in nuclear equipment.

(3) Flame retardancy: PEEK has self extinguishing property. Even without any flame retardant, it can reach the 94V-0 level of UL standard.

(4) Creep resistance: under the action of constant stress, the material has permanent deformation for a period of time, which is creep. Peek is the best creep resistance material for thermoplastic resin.

(5) Toughness and rigidity: it has high tensile strength, high stress cracking strength, especially outstanding fatigue resistance under alternating stress, which can be comparable with alloy materials.

(6) Self lubrication (wear resistance): PEEK has excellent sliding characteristics, and is suitable for occasions where low friction coefficient and wear resistance are strictly required; In particular, peek modified with carbon fiber, graphite and PTFE has excellent wear resistance.

(7) High temperature resistance: PEEK has high glass transition temperature (tg=143 ℃) and melting point (tm=334 ℃), its load thermal deformation temperature is up to 316 ℃, long-term service temperature is 260 ℃, and instantaneous service temperature is up to 300 ℃. Long term operation under high temperature and high pressure will not lose any physical properties.

(8) Hydrolytic resistance: PEEK products can still work continuously for thousands of hours without obvious performance degradation when immersed in steam at 260 ℃ or high-pressure water; Among all engineering plastics, peek has the best hydrolytic resistance and steam resistance.

(9) Non toxic: it can be used in food hygiene, medical devices and other fields.

(10) Corrosion resistance: except concentrated sulfuric acid, peek is insoluble in any solvent, strong acid and alkali, and has high chemical stability.

(11) Fatigue resistance: PEEK has the best fatigue resistance among all thermoplastic resin materials.

Application of PEEK

Polyetheretherketone (PEEK) resin is a kind of special engineering plastics with excellent performance. Compared with other special engineering plastics, it has many significant advantages, such as high temperature resistance, excellent mechanical properties, good self lubrication, chemical corrosion resistance, flame retardancy, peel resistance, radiation resistance, stable insulation, hydrolysis resistance and easy processing. It is widely used in the medical field.

Peek resin can withstand up to 3000 cycles of high-pressure sterilization at 134 ℃, which makes it suitable for the production of surgical and dental equipment with high sterilization requirements and repeated use. Peek not only has the advantages of light weight, non-toxic and corrosion resistance, but also has the characteristics very close to the elastic modulus of human cortical bone, and can be organically combined with the body. Therefore, using peek resin to replace metal to make human bones is another important application in the medical field.

Peek was first applied in clinical practice in 1999. So far, more than 5million peek products have been implanted into human body, which has become the gold standard in the field of spinal fusion. In recent years, peek is known as "the ideal material for the next generation of implantable medical products".

What are the implants made of PEEK?

(1) Bone substitutes - maxillofacial and skull implants

(2) Spinal surgery - spinal interbody fusion cage

(3) Bone and hip substitutes - joint implants

(4) Orthopaedic equipment: fixing plates and screws

(5) Dental substitutes - dental implants made with CFR-PEEK, dentures, endodontic retention

(6) Cardiac surgery - heart pumps and valves

Which companies in the world can produce long-term implantable peeks?

(1) Produced by invibio, the biomaterial Department of Victrex in the UK: peek-optima. It is the first medical implant grade PEEK material to be launched into the market. At present, it has an absolute monopoly advantage in the global market.

(2) Solvay of Belgium launched the implant grade PEEK material zeniva peek in 2009.

(3) Evonik of Germany (Evonik) entered the Chinese market at the beginning of 2014. Its trade name is vestakeep peek.

(4) Guangzhou Jusheng Medical Technology Co., Ltd., the only manufacturer in China with implant grade peek materials, has launched implant grade peek js-s1, trade name: naturegen, brand grade: js-s1.